AI PPE Detection for Factory Safety: Helmet & Jacket Monitoring

Introduction

Factory safety has always been a top priority in industries where workers are exposed to hazardous environments, heavy machinery, and strict regulatory standards. Over the years, organizations have invested in protective gear, safety training, and compliance monitoring systems to reduce workplace accidents. Among these, Personal Protective Equipment (PPE)—such as helmets and jackets—is one of the most critical safeguards.

However, ensuring every worker is consistently compliant with PPE rules is a challenge. Traditional manual monitoring methods often fail due to human error, fatigue, or sheer scale in large factories. This is where AI-driven PPE detection technologies come in. By combining computer vision, deep learning, and real-time monitoring systems, factories can automatically detect whether workers are wearing the required PPE jacket and helmet—creating a safer, more compliant workplace.

This blog explores the role of AI PPE detection for factory safety, focusing on helmet and jacket monitoring, how the technology works, its benefits, real-world applications, challenges, and the future of workplace safety in AI-driven smart factories.

Why Factory Safety Needs AI-Powered PPE Detection

1. Human Error in Manual Monitoring

In many factories, supervisors or safety officers are tasked with visually checking if workers are wearing PPE. While effective in small environments, this method quickly becomes inefficient in large-scale operations. People can overlook violations or be unable to monitor multiple areas simultaneously.

2. Increasing Regulatory Pressure

Governments and industry regulators are mandating strict compliance with safety standards. Violations related to PPE jackets and helmets can lead to heavy fines, penalties, or even shutdowns. Automated AI systems ensure real-time monitoring that minimizes non-compliance risks.

3. The Cost of Accidents

Workplace accidents not only harm employees but also cost companies millions in downtime, insurance, and legal liabilities. An AI-driven PPE detection system proactively prevents such incidents by ensuring workers are always protected.

4. The Move Toward Smart Factories

With Industry 4.0, smart factories are embracing automation, IoT, and AI solutions. Adding helmet and PPE jacket detection into factory operations fits perfectly with this digital transformation.

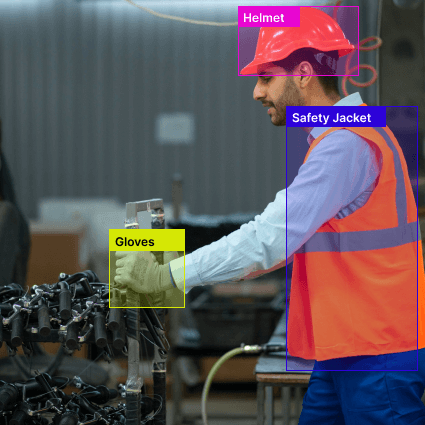

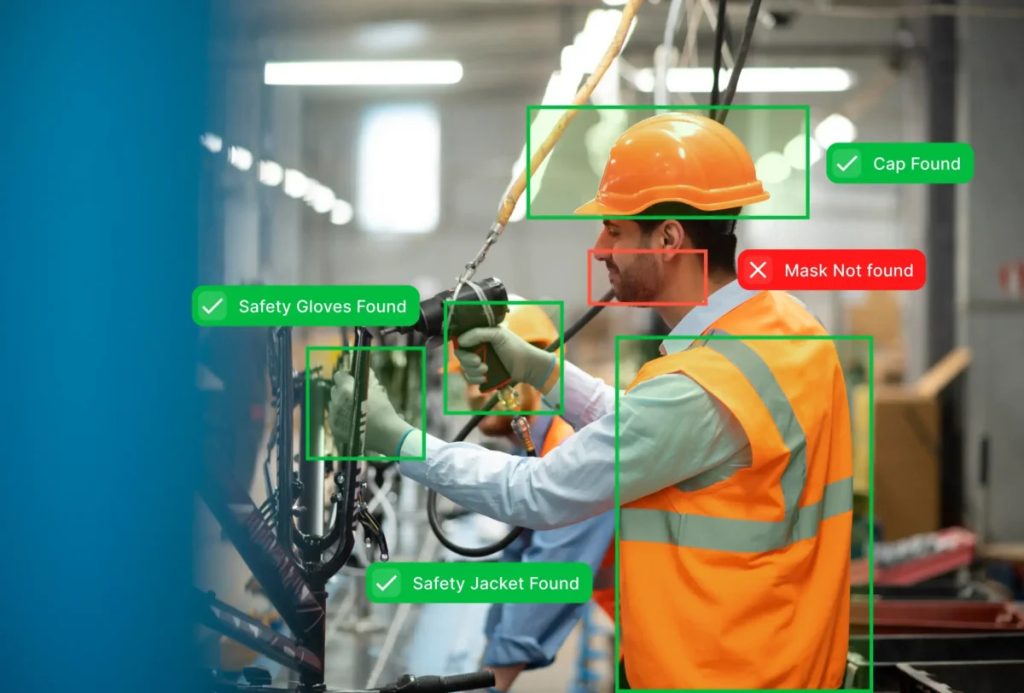

What is AI PPE Detection?

AI PPE detection is a computer vision solution that uses artificial intelligence algorithms, machine learning models, and video surveillance systems to automatically identify whether a worker is wearing proper safety gear.

For factory safety, the most critical components are:

- Helmet Detection – Ensures workers in high-risk zones are wearing protective headgear.

- PPE Jacket Detection—Confirms workers are compliant with reflective or protective jackets that improve visibility and reduce accidents.

AI models are trained using thousands of annotated images of workers wearing (and not wearing) PPE. Once deployed, the system integrates with CCTV cameras, IP surveillance, or edge AI devices to analyze video streams in real time. When violations are detected, alerts are triggered automatically.

How Helmet & Jacket Monitoring Works

- Image Capture—Factory surveillance cameras or dedicated AI cameras continuously capture video of work areas.

- AI Model Analysis—Deep learning algorithms analyze the footage to detect human figures, then check if helmets and PPE jackets are present.

- Classification & Detection—The system identifies violations by comparing workers’ appearance against trained data models.

- Real-Time Alerts—If a worker is missing a helmet or PPE jacket, the system sends an instant alert to supervisors via dashboards, SMS, or mobile apps.

- Data Logging & Reports – Violations are stored for compliance audits and safety performance tracking.

Benefits of AI PPE Detection for Factory Safety

1. Enhanced Worker Safety

The most obvious benefit is reduced risk of accidents. With real-time PPE detection, factories can ensure all employees in hazardous zones are adequately protected.

2. 24/7 Automated Monitoring

Unlike human supervisors, AI does not tire or lose focus. It provides continuous monitoring across multiple shifts and factory zones.

3. Compliance & Audit Readiness

AI systems log all violations and compliance data, making it easier to prepare safety reports and avoid penalties from regulatory authorities.

4. Increased Productivity

By automating PPE monitoring, supervisors can focus on higher-value tasks instead of constant manual inspections.

5. Scalable for Large Factories

Factories with thousands of employees can scale AI systems across multiple zones without hiring additional staff.

6. Cost Savings

Fewer accidents mean lower insurance costs, reduced downtime, and overall savings in operational expenses.

Applications of PPE Detection in Different Industries

Manufacturing Plants

In heavy machinery environments, helmets and PPE jackets are crucial. AI ensures workers stay compliant during production.

Construction Sites

Construction zones are hazardous, with falling objects and moving vehicles. AI-powered helmet and PPE jacket detection ensures worker safety.

Mining Industry

Miners face extreme conditions. AI PPE systems track compliance even in dimly lit environments using infrared-enabled cameras.

Oil & Gas

High-risk zones demand strict safety compliance. AI-powered monitoring ensures workers always wear flame-resistant PPE jackets and helmets.

Warehousing & Logistics

Forklift operations, automated storage systems, and vehicle movement make warehouses dangerous. AI ensures workers wear safety jackets for visibility.

Integration of AI PPE Detection with Factory Systems

To maximize value, AI PPE detection should integrate with existing factory systems, such as:

- CCTV and Video Management Systems (VMS)—Existing infrastructure can be upgraded with AI for PPE detection.

- Access Control Systems – Workers without helmets or PPE jackets can be denied access to restricted zones.

- IoT Sensors—Data from AI cameras can be combined with environmental sensors for advanced safety analytics.

- Centralized Dashboards – Supervisors receive alerts and real-time compliance statistics.

Challenges in AI PPE Detection

While promising, the technology faces challenges:

- Lighting & Environmental Conditions – Poor lighting or smoke can affect detection accuracy.

- False Positives/Negatives—AI may sometimes misclassify PPE due to unusual angles or occlusion.

- Initial Setup Cost—Deploying cameras and AI systems requires investment.

- Worker Acceptance – Employees may initially resist constant monitoring.

- Scalability Across Sites – Managing multiple factories requires cloud-based or hybrid solutions.

Future of AI PPE Detection in Factory Safety

The future is promising, with advancements such as

- Edge AI Devices – On-site detection reduces latency and dependency on cloud infrastructure.

- Multi-PPE Detection—Future systems will monitor gloves, boots, goggles, and ear protection in addition to helmets and jackets.

- Integration with Wearables—Smart helmets and jackets equipped with IoT sensors could integrate with AI systems for deeper insights.

- Predictive Safety Analytics—Beyond detection, AI will predict potential risks based on worker behavior and compliance patterns.

- Global Adoption—As Industry 4.0 spreads, AI PPE detection will become a standard in factory operations worldwide.

Conclusion

AI PPE detection for factory safety is transforming how industries enforce compliance and protect workers. By automatically monitoring helmets and PPE jackets in real time, factories can reduce accidents, save costs, and meet regulatory requirements with confidence.

As industries continue to embrace automation and AI, helmet and jacket monitoring will no longer be optional—it will become a standard part of every smart factory. The future of workplace safety lies in AI-driven compliance, ensuring every worker goes home safe at the end of the day.